One of the main ways to save money in a manufacturing facility is by increasing efficiencies. Be it by increasing production flow and output, reducing time, reducing scrap rates, or saving space; there are many ways to become more efficient in your facility. Improvements to your packaging are a great place to start, and the RZR Rack can help with each and every one of them.

To learn more about increasing efficiency by incorporating WIP racks, tuggers, agv’s, and mother/daughter carts, see our post here!

Depending on the rack/bag design, the RZR Rack can achieve up to 60% more parts within the same footprint when compared to a standard WIP cart that doesn’t expand.

This gives you more parts per trip for your material handlers, more parts at the line for the operators, more parts in your storage areas, and more parts per truck as you ship. All of which saves you money.

Another way to think about it is if we were to take all of your existing WIP carts, and replace them with RZR Racks, we could achieve the same number of parts in your plant, but do it with 40% less floor space, giving you more space for the things that matter like additional production lines.

This graph shows the results of utilizing the RZR Rack compared with a standard WIP cart on just one program that we ran for a customer. By switching to the RZR Rack, they were able to eliminate 172 racks and 1121 ft2 of floor space for this program.

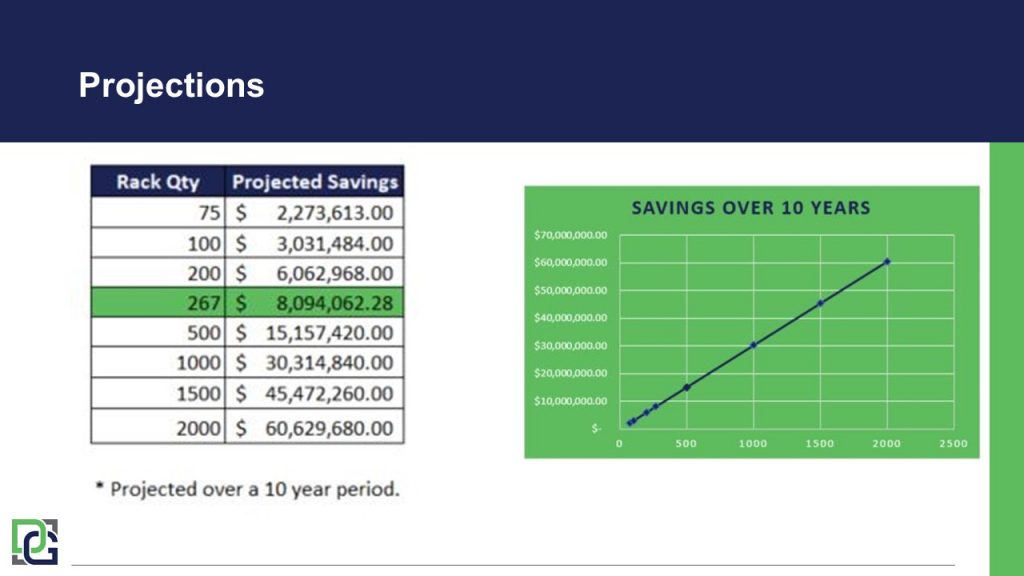

This same customer looked at the overall affect of incorporating the RZR Rack into multiple programs, and the savings they’ve achieved since doing so. They estimate that for every 75 RZR Racks they purchase, they’d need 122 standard racks to accommodate the same number of parts. That reduction in racks saves them $151,500 in annual operation expenses by reducing material handling time, labor, warehousing space, and transportation costs. Over the course of a 10-year span, they project that they’ll save $2.2 million. They’ve also calculated that the RZR Racks have a 5 month ROI when purchased, compared to their typical required 18—24 month ROI.

It’s important to remember that that is only accounting for 75 racks being purchased, and many plants can easily have 10-20 times that many. In the single program shown earlier, this would save them over $8 million over 10 years on one single program!

This doesn’t even account for the additional savings that can be realized by eliminating forklifts, incorporating mother/daughter carts, or having us retrofit your existing fleet of WIP racks. For large scale manufacturing plants, the savings can very quickly add up to 10s of millions of dollars per year.

For more information on the RZR Rack, and how it can help your facility, click here!